- 01

- Mar

膠合板冷壓機

|

膠合板冷壓機It’s a necessary equipment for processing plywood, suitable for 3’*7’,4’*8’ panel. By choosing our pressing production line, the customer could increase the production ,save energy and reduce cost. |

The cold press machine is the main equipment during plywood production line, that pre-presses the glued veneer for a short time to make it preliminarily formed, and then sends it to the hot press for pressing. The step helps to make the plywood to a basic thickness in advance, shorten the hot pressing cycle and improve the panel quality.

The plywood cold press machine comprises a feeding mechanism, a frame, press plates, plunger cylinder, lifting cylinder, hydraulic station etc. The frame part adopts a combined structure, and it is convenient for transportation.

The blank board is transported to the worktable of the cold press after assembly. Start the pump pressure then the cylinder will drop. Start pressure when the movable plate touches the blank board. The time is 20-45 minutes. Then some bonding strength of blank board will appear.

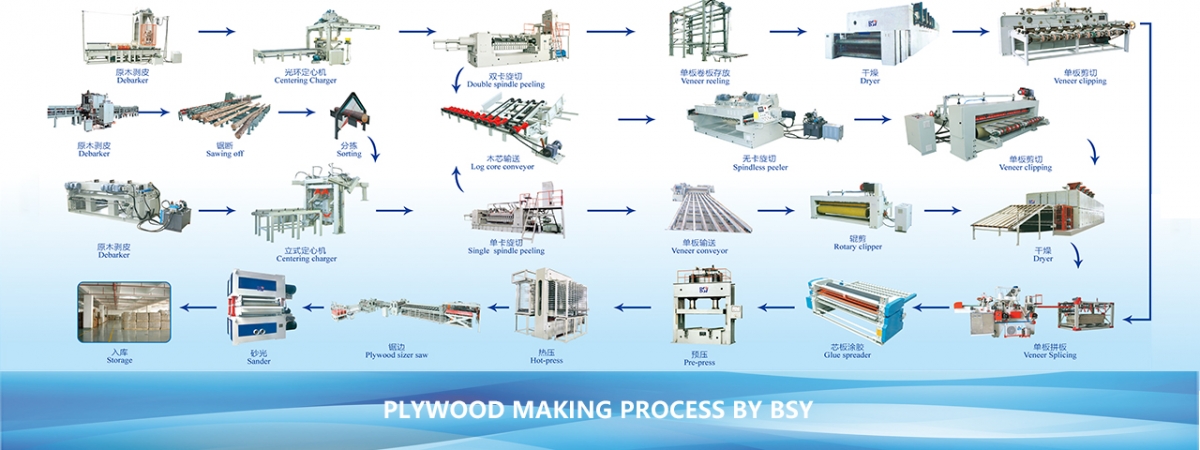

威海市百盛源實業有限公司始創於1956年,是一家木工機械製造商。

BSY產品線以一系列標準和特殊的膠合板機器為中心,包括膠合板廠、原木剝皮機、單板單軸旋轉車床、單板無主軸旋轉車床、組合旋轉車床、原木充電器、原木輸送機、單板斷頭台、膠合板表演壓力機、單板乾燥機、膠合板修邊機、膠合板砂光機等。

With the support from the Technology Development Center and all the efforts contributed by the engineers, the Group has successfully developed the most advanced plywood production line in China. Such production line has been set up in several countries, including Romania, Turkey, Russia, Indonesia, Malaysia, India, Bangladesh, Chile, Argentia etc.