- 01

- Mar

합판 콜드 프레스

|

합판 콜드 프레스It’s a necessary equipment for processing plywood, suitable for 3’*7’,4’*8’ panel. By choosing our pressing production line, the customer could increase the production ,save energy and reduce cost. |

The cold press machine is the main equipment during plywood production line, that pre-presses the glued veneer for a short time to make it preliminarily formed, and then sends it to the hot press for pressing. The step helps to make the plywood to a basic thickness in advance, shorten the hot pressing cycle and improve the panel quality.

The plywood cold press machine comprises a feeding mechanism, a frame, press plates, plunger cylinder, lifting cylinder, hydraulic station etc. The frame part adopts a combined structure, and it is convenient for transportation.

The blank board is transported to the worktable of the cold press after assembly. Start the pump pressure then the cylinder will drop. Start pressure when the movable plate touches the blank board. The time is 20-45 minutes. Then some bonding strength of blank board will appear.

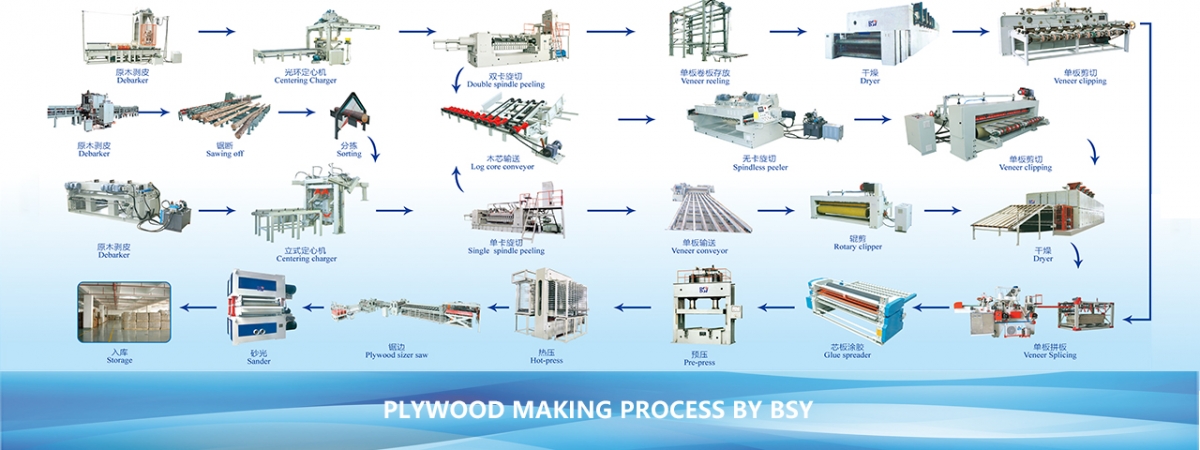

위해 BaiShengYuan 산업은 1956년부터 목공 기계 제조업체입니다.

BSY 제품 라인은 합판 공장, 통나무 박피기, 베니어 단일 스핀들 회전 선반, 베니어 스핀들 없는 회전 선반, 결합 회전 선반, 통나무 차저, 통나무 컨베이어, 단두대 단두대, 합판 수행을 포함하는 다양한 표준 및 특수 합판 기계를 중심으로 합니다. 프레스, 베니어 드라이어, 합판 엣지 트리머, 합판 샌더 등

With the support from the Technology Development Center and all the efforts contributed by the engineers, the Group has successfully developed the most advanced plywood production line in China. Such production line has been set up in several countries, including Romania, Turkey, Russia, Indonesia, Malaysia, India, Bangladesh, Chile, Argentia etc.