- 24

- Dec

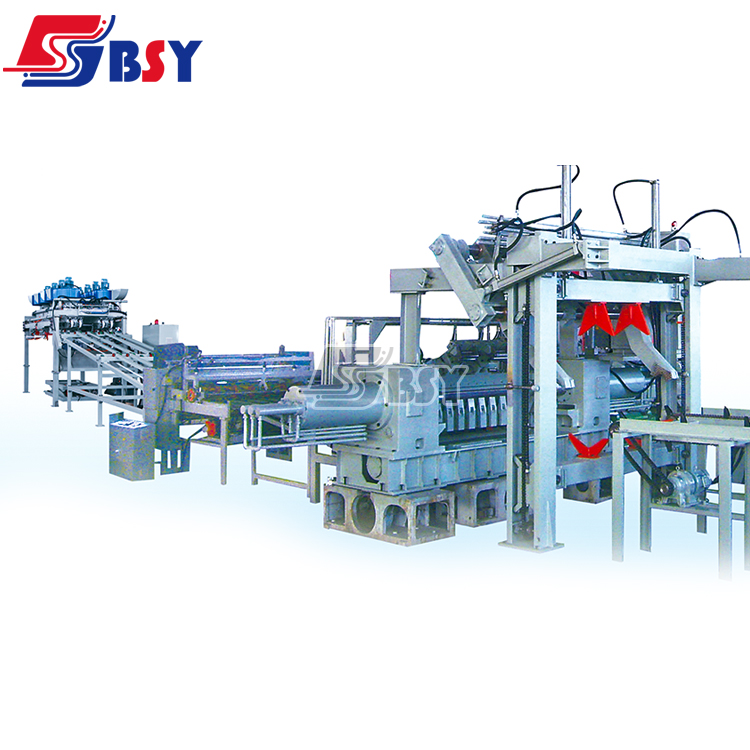

Double-Spindle Veneer Rotary Peeling Line

|

Double-Spindle Veneer Rotary Peeling Line |

According to your requirements about the budgets and capacity, BSY offers different solutions for your choice.

*Double-Spindle Veneer Rotary Peeling Line

*Single Spindle and Spindle-less Combined Veneer Production Line

*Single Spindle and Non-chuck Veneer Rotary Peeling Line

*Spindleless Veneer Peeling and Clipping Combined Production Line

With hydraulic clamping, it could adjust hydraulic cylinder press of chuck automatically according to different soft and hard wood.

Production process of Hydraulic double chuck rotary peeling line

Log conveyor → Log debarker → Automatic log centering charger → Double spindle peeling lathe → Veneer rotary clipper →Veneer conveyor → Veneer stacker

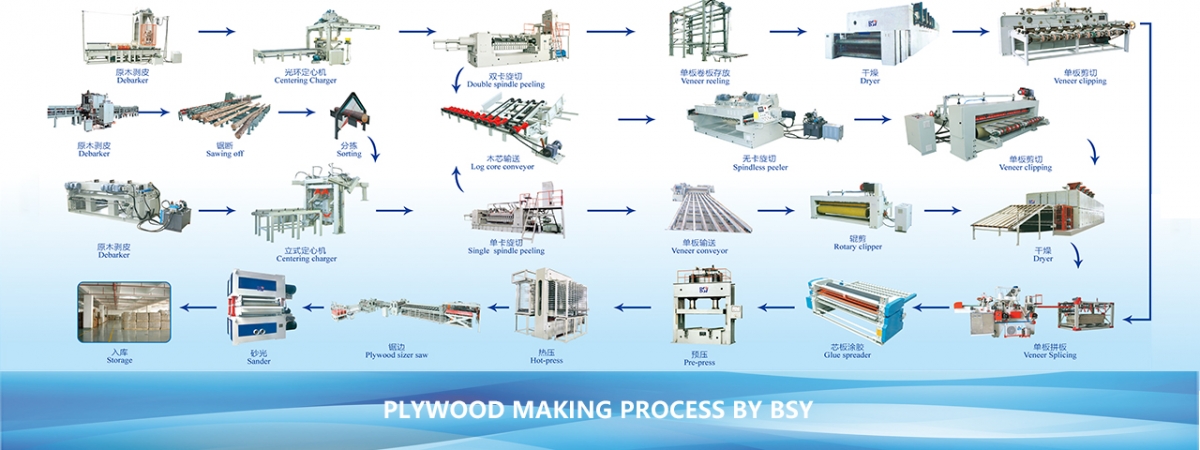

The Group always focus on new technology development. It self-owns the Provincial Woodworking Machinery Technology Development Center which is funded by the government. With the support from the Technology Development Center and all the efforts contributed by the engineers, the Group has successfully developed the most advanced plywood production line in China. Such production line has been set up in several countries, including Romania, Turkey, Russia, Indonesia, Malaysia, India, Bangladesh, Chile, Argentia etc.

We won praise from overseas customers for good quality products and intimate service.

Products are exported to more than 50 countries and regions.

We’ve passed the ISO9001:2018 quality management system certification and the CE certification.