- 21

- Apr

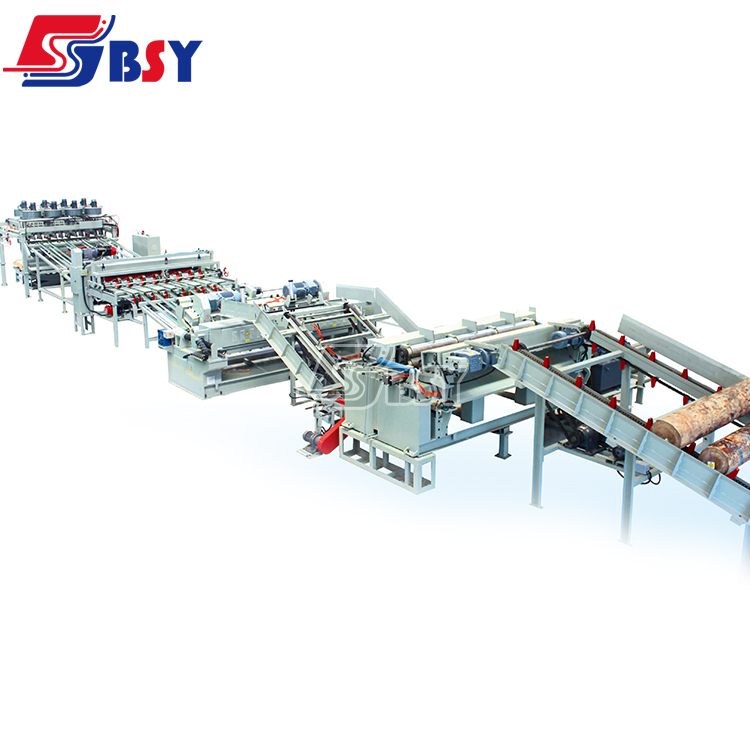

Spindleless Rotary Veneer Production Line

|

Spindleless Veneer Production LineProceso de producción: Log conveyor-Log debarker- Veneer peeler-Veneer clipper- Veneer stacker |

GBX2600/5 high-speed intelligent spindle-less rotary veneer production line, established a digital model for control of non-chuck rotary veneer peeling line, realized full automatic production from log debarking, veneer peeling, veneer cutting to veneer stacking, which has gained independent intellectual property rights.

Among them, the log debarker is equipped with a power roller, and innovative designs carried out on the ”SL2600/5B CNC spindleless veneer rotary peeling machine” , such as double-roller worktable movement, automatic adjustment of the knife gap, add the knife to automatically change the angle, which effectively improves the yield of veneer, the surface finish of veneer and the precision of rotary peeled veneer, the project was unanimously recognized as reaching the international advanced level.

The production line processes logs with a diameter of 130-500 mm, a maximum log length of 2600 mm, a maximum rotary peeling diameter of 480 mm, a peeled veneer thickness of 0.5-3.0 mm, and a peeling speed of 0-80 m/min. The capacity of veneer production line reaches 15,000 m3/a.