- 15

- Dec

Log Debarker

|

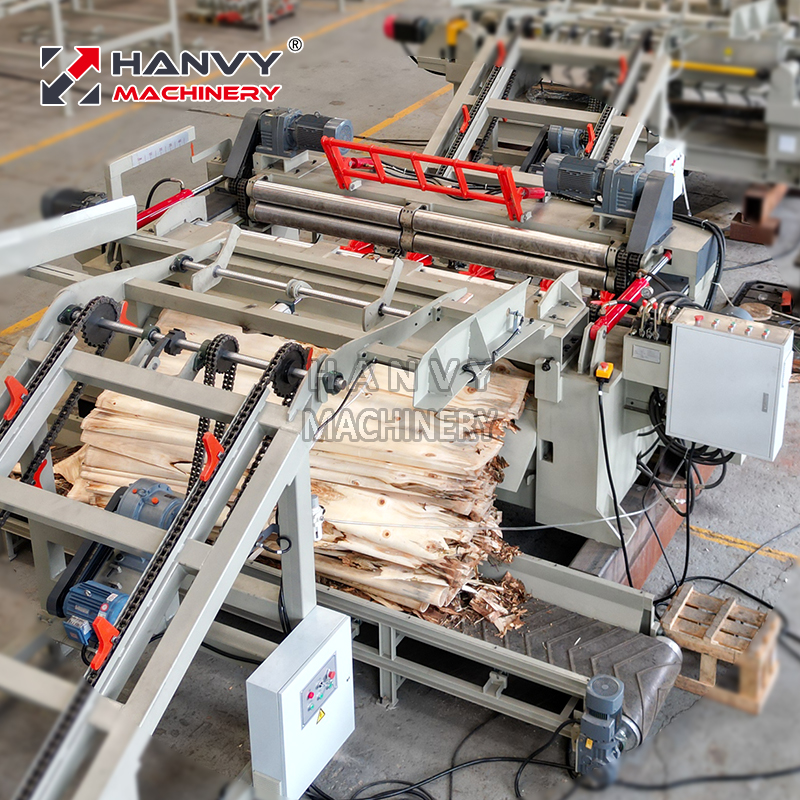

Log DebarkerWorking length : 4ft,5ft,8ft,10ft or customized Max.working diameter : 300~600 mm Rotary speed: 60 m/min Voltage: 380v/220v/customized Certification: CE , ISO 9001 |

This machine adopts rotary cutting principle of non-chuck rotary veneer lathe, could remove the bark quickly and effectively, save labor cost and improve the efficiency.

This machine adopts rotary cutting principle of non-chuck rotary veneer lathe, could remove the bark quickly and effectively, save labor cost and improve the efficiency.

* Feeding with hydraulic controlling, could improve efficiency.

* Equipped with small rotation spindle, helps to work with bend log.

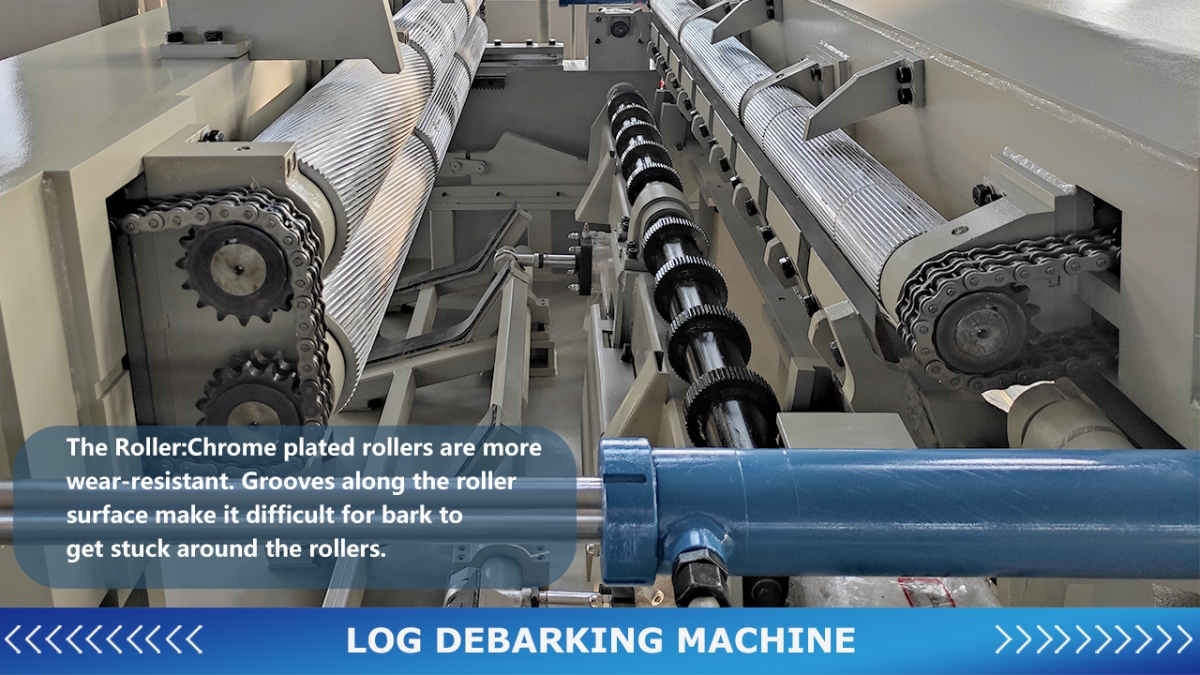

* With enlarged diameter roller, increase rotary peeling speed.

* Knife-gap auto change during the debarking process.

* With high-quality steels and bearing,it’s longer service life than common debarkers.

* A front and back feed keeps the logs moving in and out of the debarker efficiently, and a

large oil pump keeps the feeds well-lubricated and working smoothly.

* A manual reverse switch with a self-reset function responds quickly for convenient and safe use.

* Working length and max working diameter could be customized.

At Hanvy, “one‑stop shop” means more than a slogan. Whether you need a single veneer dryer or a turnkey, fully automatic production line, our end‑to‑end process is built around you.

Whether you need a standalone veneer dryer or an entire, fully‑automatic plywood production line, Hanvy Machinery delivers. Our extensive product portfolio includes:

Log Cutting Lines for precise, high‑capacity debarking and cutoff

Veneer Peeling Lines engineered for minimal waste and superior surface quality

Veneer Drying Lines, with TÜV Rheinland accreditation, that ensure uniform, energy‑efficient moisture removal

Gluing & Pressing Systems optimized for rapid cycle times and consistent bond strength

Trimming, Sawing & Sanding Lines that deliver impeccable edge finishes

Sorting & Buffering Systems, Putty & Coating Lines, and Automatic Bundle Strapping Machines—every stage, every need covered.

Patented Technology & International Certification

Our R&D team holds a portfolio of national invention and utility model patents, reflecting our dedication to research and continuous improvement. We maintain ISO 9001–certified quality management, and many of our machines—especially veneer dryers—carry CE marking and TÜV Rheinland approval. These certifications guarantee not only performance and safety, but also compliance with even the most stringent global standards.