- 09

- Jun

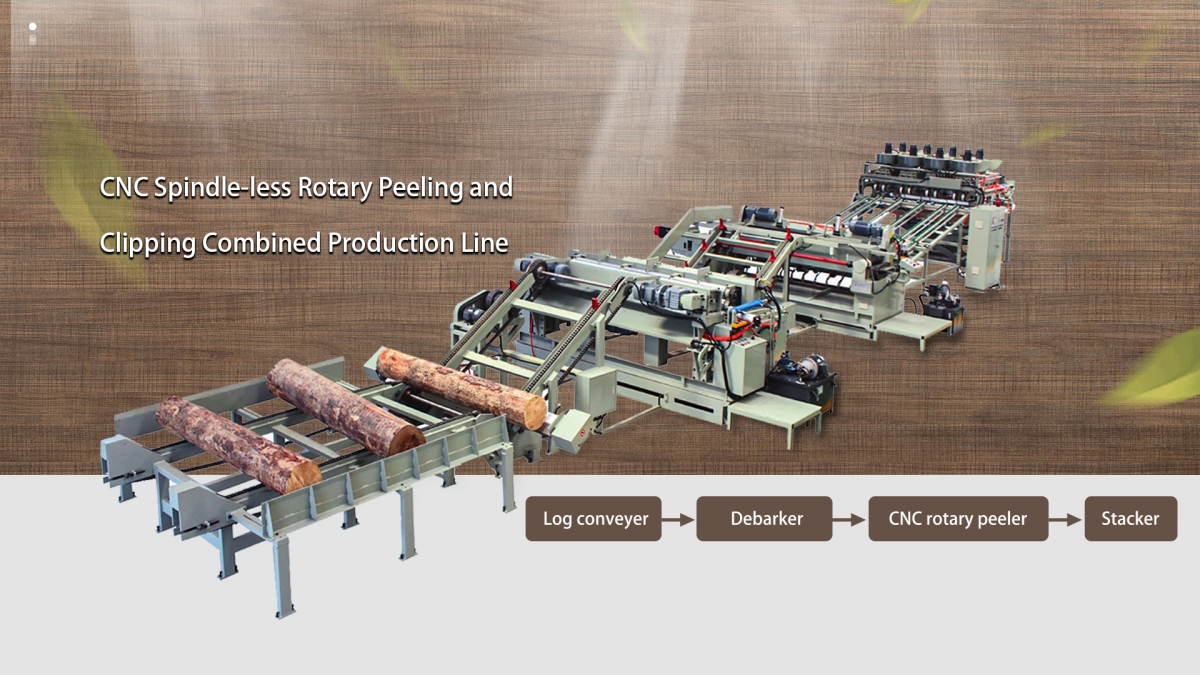

CNC Veneer Peeling combined Clipping SLK(J)2600/5F

|

CNC Non-chuck Veneer Peeling and Clipping Combined MachineModel: SLK(J)2600/5F Peeling speed: 30~80 m/min Peeling diameter: ø60~480 mm |

According to customers’ different requirements about the log diameter, log length, veneer thickness, budget, we supply customized project and recommend the fit machines for you.

Features of the CNC non-chuck peeling combined clipping SLK(J) series:

* Linear Guide & Ball screw used for feeding

* Mitsubishi system

* Rear angle electric adjustment

* Gear transmission

* Automatic adjust the knife gap

* Hydraulic press the knife

The gap between the pressure ruler and the rotary knife is driven by servo motor, which can solve the problem of changing the parameters of the knife gate when rotary cutting different tree species and different thicknesses. Two kinds of knife gates can be preset through servo control. During work, the pressing rate of the pressure ruler and the veneer can be changed at any time, so as to reduce the degree of back cracking of the veneer, improve the smoothness of the veneer, and solve the problem of poor quality of the traditional non-jamming rotary cutting veneer. problem.

| Model | SLK(J)2600/5F | |

| Max.rotary cutting length | mm | 2600 |

| Max.rotary cutting diameter | mm | Ø480 |

| Output speed | m/min | 40~80 |

| Veneer thickness | mm | 0.5~3 |

| Final log core diameter | mm | Ø60 |

| Peeling knife size | mm | 2760x200x16 |

| Cutting knife size | mm | 2750x120x12 |

| Feeding servo motor power | kw | 11 |

| Single roller feeding motor power | kw | 3.5 |

| Total power | kw | 72.2 |

| Overall size | mm | 5110x2150x2060 |

| Weight | kg | 14200 |

BSY product line centers on a range of standard and special plywood machines that includes plywood plant , Log debarker, veneer peeling lathe, log charger, log conveyor, veneer guillotine, plywood performing press, Veneer Dryer, plywood Edge Trimmer, plywood Sander , etc.

*More than 60 years of experience, we are one of the leading manufacturer of woodworking machines in China,

*Specializing in plywood production line,our prodessional R&D team could supply the project to meet your requirement.

*More than 10 QC staffs with more than 20 years working experience to control the production quality.

*Having own after –sale maintenance center, our engineer can go to overseas for installation and commissioning.